The future of construction and engineering safety compliance management

by

Metam technologies

Abstract

Explore the future of safety compliance in construction and engineering, from digital transformation to AI-driven solutions. This comprehensive guide covers the latest trends, technologies, and best practices for navigating complex regulations and ensuring business continuity in an ever-changing industry.

Table of Content

What is construction and engineering safety compliance management?

What are the key trends shaping the future of construction and engineering safety compliance?

How can emerging technologies enhance safety compliance in construction?

What are the challenges in construction and engineering safety compliance?

How can construction firms achieve long-term compliance and business continuity with Metam Technologies?

Key takeaways

In the fast-evolving world of construction and engineering, safety compliance management has become increasingly vital. As industry regulations grow more complex and technology continues to innovate, businesses face new challenges in ensuring they meet safety standards.

In this article, we will explore the future of construction and engineering safety compliance management, focusing on emerging technologies, best practices, and the role of long-term business continuity. The future of safety compliance is not only about meeting regulations but also leveraging new technologies to enhance safety, reduce risk, and ensure operational efficiency.

In 2025, the global construction industry is projected to spend over $1.5 trillion on safety management systems, with a significant shift towards AI and IoT-based solutions for compliance and risk mitigation.

What is construction and engineering safety compliance management?

Definition

Construction and engineering safety compliance management is a comprehensive and systematic approach to ensuring that all activities within construction and engineering projects adhere to relevant safety laws, regulations, standards, and best practices at the local, state, and national levels. It encompasses the proactive development, implementation, and continuous improvement of processes, policies, and technologies aimed at protecting the health, safety, and welfare of all stakeholders, including workers, subcontractors, visitors, and the public.

Effective safety compliance management goes beyond mere adherence to legal requirements. It involves cultivating a strong safety culture, proactively identifying and mitigating hazards, providing comprehensive training, ensuring the proper use of personal protective equipment (PPE), maintaining thorough documentation, and establishing clear incident reporting and investigation procedures. The ultimate goal is to minimize accidents, injuries, and occupational illnesses, thereby improving operational efficiency, reducing costs associated with incidents, enhancing a company's reputation, and fostering a healthy and safe work environment.

Key aspects of construction and engineering safety compliance management

Construction and engineering safety compliance management refers to the processes, policies, and technologies used to ensure that construction projects adhere to local, state, and national safety regulations.

Key aspects of construction and engineering safety compliance management include:

- Developing a safety culture: Embedding safety as a core value within the organization through leadership commitment, worker participation, and open communication. For example, regular safety stand-down meetings to discuss potential hazards.

- Hazard identification and risk assessment: Systematically identifying potential hazards associated with construction and engineering activities and evaluating the associated risks to implement appropriate control measures. This could involve job safety analyses (JSAs) before starting critical tasks.

- Regulatory compliance: Staying informed about and adhering to all applicable safety regulations and standards issued by bodies such as OSHA (in the US), and other relevant authorities. This includes understanding and implementing updates to building codes and safety protocols.

- Safety training and competency: Providing comprehensive safety training to all personnel, ensuring they have the knowledge and skills to perform their tasks safely. This includes initial training, regular refreshers, and specific training for operating equipment or handling hazardous materials.

- Personal protective equipment (PPE): Ensuring that appropriate PPE is available, correctly used, and maintained by all personnel. Examples include hard hats, safety glasses, and high-visibility vests.

- Safe work procedures: Establishing and communicating clear and concise safe work procedures for high-risk activities. For instance, a detailed step-by-step procedure for working at height.

- Incident reporting and investigation: Implementing a system for promptly reporting and thoroughly investigating all incidents, including near misses, to identify root causes and prevent recurrence.

- Emergency preparedness and response: Developing and practicing emergency response plans for various potential scenarios, such as fire, medical emergencies, and severe weather. Regular drills help ensure effective response.

- Auditing and inspections: Conducting regular safety audits and inspections of work sites, equipment, and procedures to verify compliance and identify areas for improvement.

- Documentation and record keeping: Maintaining accurate and up-to-date records of safety plans, training, inspections, incidents, and corrective actions.

- Continuous improvement: Regularly reviewing and updating safety management systems based on performance data, lessons learned from incidents, and changes in regulations or best practices.

Regulatory Bodies and Standards

Several key regulatory bodies govern safety standards in the construction industry, including the Occupational Safety and Health Administration (OSHA), the Environmental Protection Agency (EPA), and the National Institute for Occupational Safety and Health (NIOSH). These organizations set specific guidelines that businesses must follow to ensure compliance.

Non-compliance with these regulations can result in penalties, legal consequences, and project delays. Understanding these standards and adapting to them is a key challenge for construction firms looking to stay ahead in a competitive landscape.

What are the key trends shaping the future of construction and engineering safety compliance?

As the construction industry becomes more complex, it faces new challenges in ensuring safety compliance. Several key trends are reshaping how compliance is managed in the industry, ranging from digital transformation to evolving safety regulations.

Rise of digital transformation in safety compliance

Emerging technologies like AI, IoT, and big data analytics are revolutionizing how construction companies manage safety compliance. These tools offer real-time monitoring, predictive analytics, and automated reporting, enabling construction firms to stay ahead of potential safety issues.

AI-powered tools can analyze historical data to identify patterns that predict safety risks, while IoT devices can monitor environmental conditions and worker health in real-time. By embracing these technologies, companies not only enhance their safety protocols but also streamline their compliance processes, saving time and reducing manual effort.

Evolution of safety regulations and standards

As construction projects grow larger and more complex, safety regulations have become more stringent and multifaceted. Local, state, and national regulations now cover an increasingly broad range of factors, from worker safety to environmental protection. Companies must stay updated on these evolving regulations, which can vary depending on the project location and the type of work being done. Adapting to these changes requires robust systems that can monitor and adjust to new regulatory requirements quickly.

Increased focus on risk management and preventative strategies

The focus is shifting from reactive safety measures to proactive, preventative strategies. Predictive analytics tools that leverage machine learning and historical data can now anticipate risks before they occur. These tools allow companies to plan ahead and mitigate risks early, reducing the likelihood of accidents and improving overall safety on the job site.

Integration of automation in safety compliance

Automation is playing an increasingly important role in simplifying safety compliance management. From automated reporting to real-time monitoring, automation reduces human error and ensures compliance with minimal manual effort.

Automated tools can track safety regulations, flagging non-compliance issues in real time and notifying relevant personnel. This reduces the time spent manually reviewing documents and allows companies to focus on more strategic initiatives.

How can emerging technologies enhance safety compliance in construction?

New technologies are transforming the way safety compliance is managed on construction sites. From AI-driven solutions to IoT devices and automation tools, these technologies are providing unprecedented opportunities to improve safety and ensure long-term compliance.

- AI and machine learning: AI-powered compliance tools can analyze vast amounts of data to identify potential hazards and safety risks. These systems continuously monitor construction activities and flag any issues that could compromise safety, such as improperly stored equipment or hazardous conditions. By automating data collection and reporting, AI also ensures accurate compliance tracking, reducing the burden on human teams and minimizing the risk of errors.

- Internet of Things (IoT): IoT devices, such as wearables and sensors, are revolutionizing on-site safety management. These devices can track workers' health metrics, such as heart rate and body temperature, providing real-time alerts when a worker may be in distress. IoT devices also monitor environmental conditions, such as air quality or machinery performance, ensuring that construction sites remain safe and compliant with environmental regulations.

- Drones and robotics: Drones and robotics are becoming essential tools for enhancing compliance in hazardous environments. Drones are used for site inspections, capturing high-quality images and data in real-time. These inspections allow safety officers to spot potential risks from a safe distance. Robotics can also assist with dangerous tasks, such as inspecting structural integrity in hard-to-reach areas, reducing the need for human workers to perform risky operations.

- Blockchain: Blockchain technology offers a decentralized and immutable record-keeping system that can enhance safety compliance management. By using blockchain to track safety data, construction companies can ensure that all records are transparent, secure, and tamper-proof. This creates a reliable history of compliance activities, which is particularly valuable in case of audits or legal disputes.

- Virtual Reality (VR) and Augmented Reality (AR): VR and AR are transforming safety training by providing realistic simulations for high-risk scenarios. Workers can experience hazardous situations in a controlled virtual environment, which enhances their ability to respond to real-life challenges. These immersive training tools improve safety awareness and reduce the likelihood of accidents.

- Big data analytics: Big data analytics is another powerful tool in predicting and mitigating safety risks. By analyzing historical safety data, construction firms can identify trends and patterns that point to potential hazards. Predictive analytics tools allow companies to address issues before they escalate, minimizing accidents and improving overall safety.

What are the challenges in construction and engineering safety compliance?

Despite the many advances in safety technology and compliance management, several challenges remain for construction firms. These challenges include staying updated with changing regulations, training workers, managing data privacy concerns, and balancing the costs of compliance.

- Staying updated with changing regulations: With safety regulations continually evolving, it can be challenging for construction companies to stay informed about the latest rules and requirements. Implementing digital dashboards and automated alerts can help firms stay ahead of regulatory changes, ensuring that they are always in compliance.

- Training and skill gaps in safety compliance: As new technologies emerge, there is a growing need for specialized training to ensure workers understand how to use these tools properly. Bridging the skill gap through ongoing training and certification programs is essential for keeping employees informed about the latest safety practices and technologies.

- Data management and privacy concerns: The increased use of digital tools to collect safety-related data raises concerns about privacy and data security. Construction companies must ensure that all safety data is stored securely and that it complies with relevant data protection laws.

- Cost of compliance and resource allocation: Maintaining compliance can be costly, especially for large construction firms. Proper resource allocation and finding cost-effective safety management tools can help companies balance the need for compliance with the desire to minimize overhead costs.

- Managing multi-site compliance and coordination: Construction companies with multiple project sites often face challenges in managing compliance across diverse locations with varying regulations. Implementing a centralized compliance management system can help streamline the process and ensure consistent safety practices across all sites.

- Integration of new technology with existing systems: Integrating new safety technologies into existing systems can be challenging. Overcoming resistance to change and ensuring seamless adoption of new tools is crucial for maintaining continuous safety compliance.

How can construction firms achieve long-term compliance and business continuity with Metam Technologies?

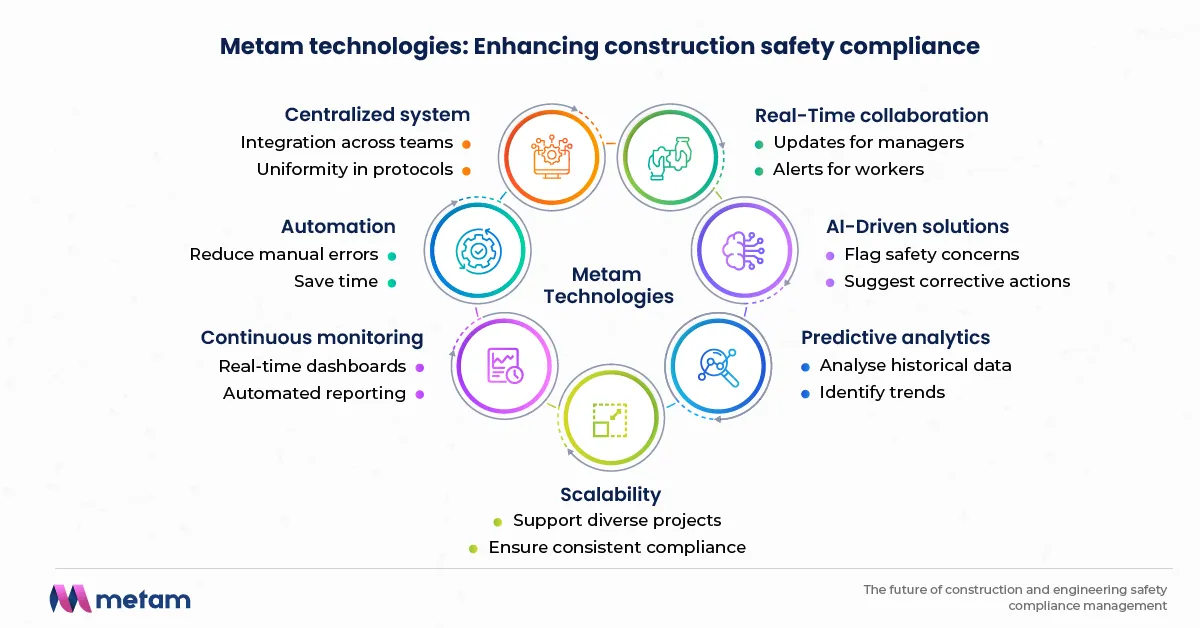

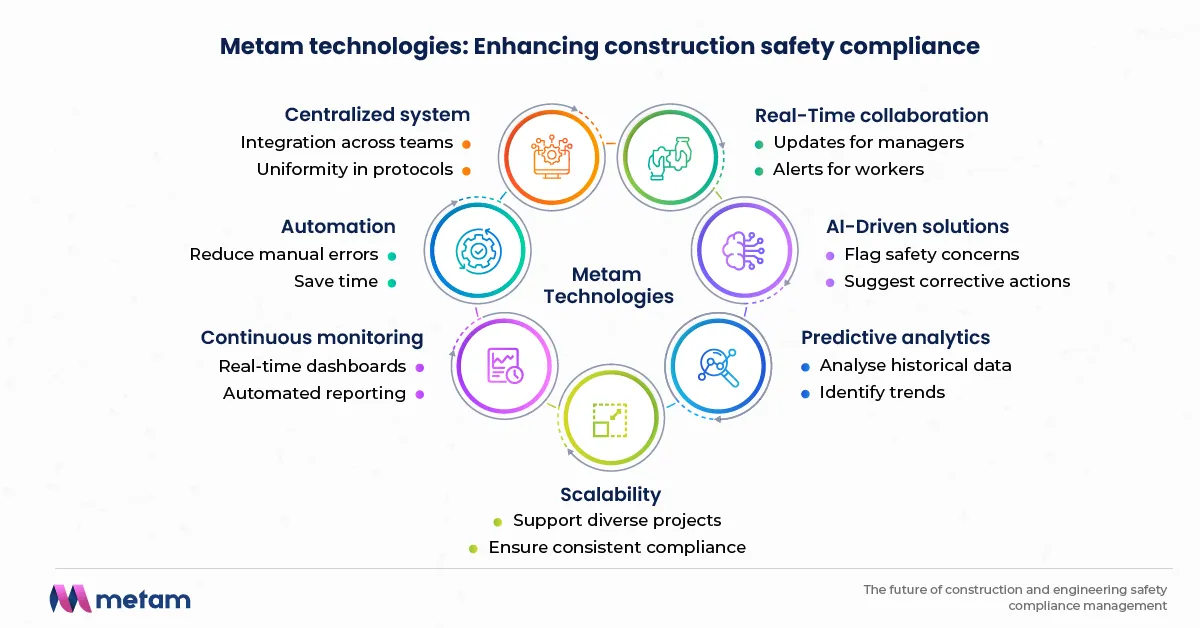

Metam Technologies integrates a variety of solutions to streamline construction and engineering safety compliance and risk management. By automating processes, providing real-time monitoring, and offering predictive analytics, Metam ensures that construction companies can proactively manage safety and compliance challenges. These solutions help firms maintain a high level of operational efficiency while minimizing risks and ensuring business continuity in the long term.

Metam supports long-term compliance and continuity

- Automation of safety management tasks: Metam Technologies offers solutions that automate compliance workflows, ensuring that safety checks, inspections, and audits are performed consistently and accurately. Automation reduces manual errors, saves time, and allows staff to focus on proactive safety management rather than administrative tasks.

- AI-driven solutions for real-time risk assessment: Metam's AI-powered tools analyze vast amounts of data to assess potential risks in real time. By automatically flagging safety concerns and suggesting corrective actions, the system helps construction teams address issues before they escalate, reducing the likelihood of accidents and improving compliance.

- Predictive analytics for proactive decision-making: Metam’s predictive analytics tools help construction firms anticipate potential safety risks and operational challenges before they arise. By analyzing historical data and current trends, companies can make informed decisions that mitigate risks and ensure compliance throughout the project lifecycle.

- Continuous monitoring and reporting: Continuous monitoring is essential for staying ahead of safety compliance challenges. Metam’s platform offers real-time dashboards that provide up-to-date insights into compliance status, safety metrics, and operational performance. Automated reporting tools ensure that managers are always informed of potential risks, enabling swift responses to maintain safety standards.

- Centralized safety management system: With Metam’s centralized platform, construction companies can manage all safety compliance data in one place. This integration allows for seamless coordination across multiple teams, projects, and sites, ensuring uniformity in safety protocols and compliance standards.

- Real-time collaboration and communication: Metam’s solutions enable real-time communication and collaboration among safety managers, site supervisors, and field workers. Instant updates, alerts, and notifications ensure that safety issues are addressed quickly and collaboratively, improving response times and ensuring compliance at every level.

- Scalability for multi-site operations: For construction companies operating across multiple sites, Metam’s platform ensures consistent safety compliance across all locations. The system’s scalability supports diverse project sizes, providing flexible solutions that grow with the needs of the business.

Key takeaways

As technology continues to advance, the future of safety compliance in construction and engineering is being shaped by AI, IoT, and automation. Construction firms must stay updated with changing regulations, invest in training, and leverage emerging technologies to improve safety and efficiency. By adopting digital tools like those offered by Metam Technologies, companies can streamline compliance management, reduce risks, and ensure business continuity.

Construction compliance...

This article explores the transformative role of compliance automation in construction health and safety management,...